Rane Madras Limited in Chennai is the major OEM of car parts, recognised around the world for its advanced technologies.

Rane Madras Limited is a major OEM of car parts that have, in addition to five factories in various locations in India, just build an exclusive new factory in Gujarat which is becoming a centre of the automotive industry. In 2008, they embarked on a waste management project with Mitsubishi Electric. This was initiated because of power shortages and conservation needs due to production increases...

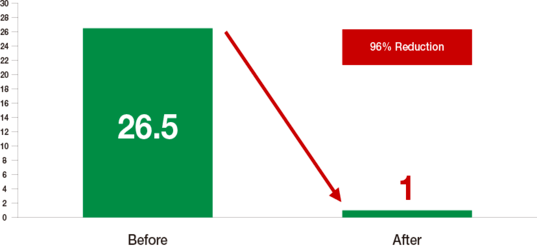

Rane Madras Limited started a project focusing on eliminating four wasteful inefficiencies. The drill that consumes energy because it keeps spinning even when it is not used, the use of a powerful motor when it's not needed, older and less efficient machines that waste power used, and finally the motor supplying more power to the press machines than they require. Mitsubishi Electric's inverter was the key device that helped eliminate the waste of power. Rane Madras Limited installed the inverter to all 546 machines in its factory.

In the case of the pressing process, with the inverter, 98% of energy was saved.

This project started in 2008 realised a significant reduction in annual power consumption of 3.8lakhs (0.38million units) in 2013.

According to the project leader, it saves approx. Rs.30lakhs of electricity per year.

This project resulted not only in energy savings, but also motivated employees to be aware of saving energy. As a result, the first Deming Prize* in India was awarded. One of the important reasons that they received the award was for reducing energy costs.

*Deming Prize Global quality award, created in Japan that recognises organisations for their contributions to the field of Total Quality Management (TQM).

Mitsubishi Electric's inverter converts the electrical voltage and frequency of electrical devices and adjusts rotational speed of motors.

By combining the inverter with a programmable logic controller (PLC), users can realise higher energy savings. Mitsubishi Electric is a leading manufacturer of Factory Automation Products – like Inverters, Motion Controllers, Programmable Logic Controllers and Human Machine Interface.

The Rane Madras Limited example is one of the representative cases of Mitsubishi Electric?? solutions worldwide.

Our solutions are already installed at many companies in India across various market segments such as Automotive, Pharmaceutical, Food and Beverage, Textile, Water and Waste Water Treatment, Tunnel Ventilation, Power Distribution in Premium Residential and Commercial Buildings.

In addition to five factories that build separate automotive parts, they built an exclusive factory in Gujarat that produces energy saving components for OEMs worldwide.

[Delivery date] 2008 [Delivery record] FA System: Micro PLC, VFD, Servo Motor