Robotics is a field that has advanced by leaps and bounds to become what it is today. However, regardless of how common robots have become, getting confused about what a particular robot does is quite commonplace. With that said, let us now discuss the two most common types of robots that are being used in various industries today.

Industrial robots are used to automate the process of manufacturing almost completely without the need for human intervention. We are all well aware of their contribution towards saving time and money and increasing productivity. Now, on the other hand, imagine a workplace where robots are working alongside human employees. These robots are known as collaborative robots or cobots. They are versatile and user-friendly tools that allow businesses to enhance quality and improve productivity.

People looking to automate their manufacturing processes often face the question of whether they should choose industrial robots or collaborative robots. Here’s more on how these two are different from each other: -

A cobot can double up as an assistant to a human operator. It is designed to work in partnership with humans. Traditional robots, on the other hand, are programmed to finish an automated task with very little or no human interaction.

When compared to industrial robots, cobots are easier to program. In fact, one of the most marketed features of collaborative robots is the ease of programming. They are made in such a way that they are extremely easy-to-use as well.

Cobots are designed to work alongside people. This means that they are safe enough to function around humans and hence do not need the safety infrastructure that industrial robots require.

Industrial robots are capable of handling larger, heavier materials like the ones used in auto manufacturing. Hence, they are well-suited for heavy manufacturing. Cobots, on the other hand, aren’t designed for heavy manufacturing owing to their size and their requirement of working in proximity to human employees.

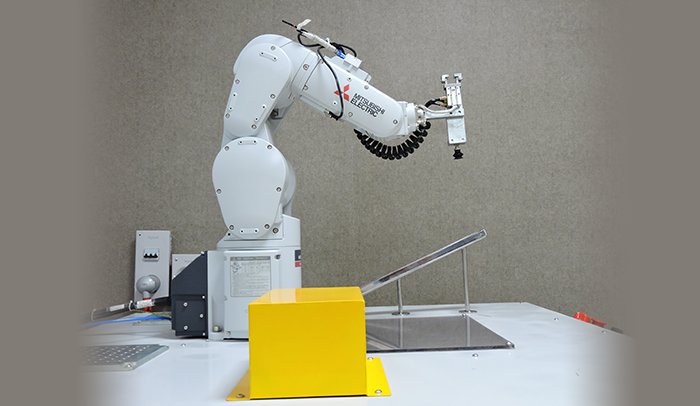

Traditional industrial robots are usually fixed equipment created for extremely high-precision, high-volume, and high-speed production.

As far as cobots are concerned, they are well suited for manufacturers with low volume, high-mix production or those who want to safely automate processes alongside workers.

As compared to conventional robots, cobots can easily be moved and used in various areas of production. A majority of them can easily be mounted on any surface. Moreover, they are often lightweight enough to be carried by a single person.

The aim of robotics and industrial automation is to increase speed, efficiency, and overall performance. Both industrial robots and collaborative robots come with their own sets of features and benefits and can be chosen based on the expected application.

Known for offering factory automation systems, Mitsubishi Electric is a brand that is widely trusted for its range of industrial and collaborative robots. The industrial robots are well-known for their high speed and accuracy. On the other hand, Mitsubishi Electric offers a collaborative robot called MELFA ASSISTA that not only allows ease of operation but also doesn’t require any robot programming expertise.