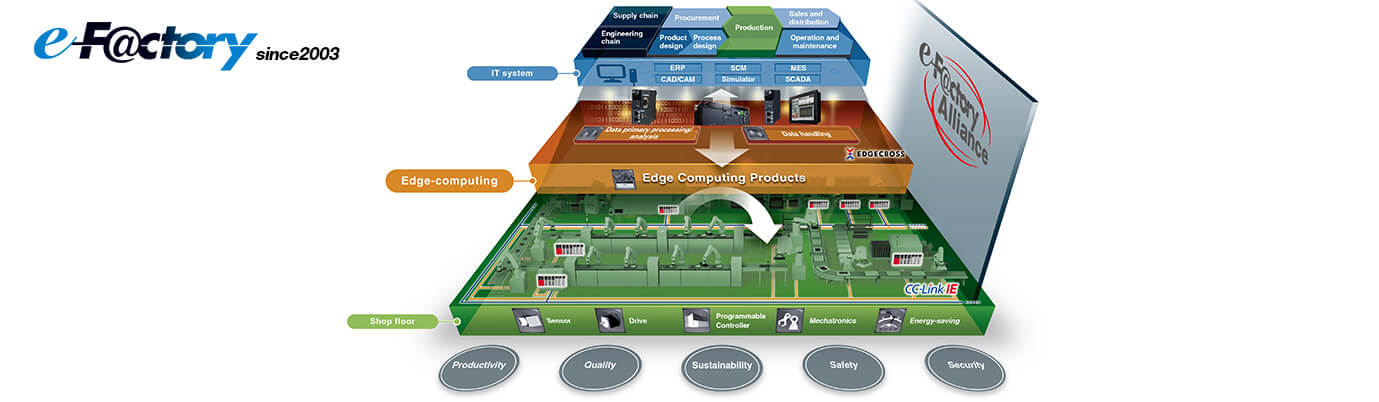

The fourth industrial revolution is here and very rightly has become the talk of the town. Emerging globally as a powerful force, Industry 4.0 is characterized by digitization and interconnection of products, value chains and business models. It is driven by an amalgamation of technologies such as Internet of Things (IoT), artificial intelligence, data volumes, business analytics, computational power, augmented reality, elemental design, advanced robotics, simulation, additive manufacturing, cyber-physical systems and sensor based technologies. It results in 'Smart Factory', which is characterized by resource efficiency in the factory processes along with higher reliability and a conspicuous improvement in the quality of the output as well.

Though India focuses on Service Sector for growth, the Manufacturing Sector needs to play a significant role in the Indian economy. ‘Make in India’ program launched by Government of India is aimed at placing India on the world map as a manufacturing hub. The SMEs industry in India plays a pivotal role in building economy and provide a large share of employment.

With Big-Data-Driven Quality Control, the number of workers required in quality control will be reduced but there will be an increase in demand for industrial data scientists.

No doubt with the advantages of Industry 4.0 the demand for highly skilled workers in IT, analytics, and R&D roles will increase, as well as new jobs will be created resulting from the types of revenue growth opportunities.

SMEs play an important role in Smart Manufacturing. SMEs should focus on quality, efficiency, traceability and collaboration. India is a dynamic and growing market with lots of opportunities and a few challenges. Challenges with Indian Manufacturers are:

One of the major contributors to smart manufacturing is IT, which is reckoned as backbone of the sector. Fortunately, India is a talent-rich country, especially in the IT sector which is full of opportunities. In the future, India can create its own path for smart factories. To strengthen India’s manufacturing sector, the SMEs should be encouraged to become partners with larger organizations that can provide various customized solutions to Indian manufacturers.

Indian SME sector should look up to market leaders for technological assistance, which can enable Indian companies to explore markets in other Asian countries. Most of the SMEs in India have good technical capabilities, however, they need to implement and improve processes of Design and Quality Measurement. The role of industry 4.0 in the SME sector will will help them to expand their horizons and help them explore markets in Asian countries other than India. Apart from helping them with technological assistance, market leaders can also help them in strategy formulation and quality assessment.

Mega trends those are transforming India economy is Urbanization: Now SMEs can see opportunity by visualizing city as a customer, Infrastructure Development, Smart is the new green, Innovating to zero: e.g. zero defects, zero debt.

Presuming that complete automation is not the realistic view, it can be said that one of the benefits of Industry 4.0 is that it will increase productivity through a mix of physical and digital assistance systems. This will happen as the technological advancements brought by Industry 4.0 will mean that physically demanding or routine jobs will decrease, while the demand of jobs that require problem solving, flexible responses, and customization will go up. The employees might have to combine the skills of know-how related to a job with IT competencies.

Some key challenges in manufacturing after realization of Industry 4.0 potential are lack of a clear digital vision, fostering a strong digital culture, data security, Level of digitization, a lack of data analytical capabilities, lack of standardization, prevalence of proprietary standards is going to be a key roadblock, and the major risk with recording, storage and analysis of large volumes of customer data is the inappropriate use of the said data.

By adopting Industry 4.0 standards, SMEs or the manufacturing units reap rewards such as Lower Cost, Optimized customer relationship, Additional Revenue, Clarity on the status of production system in real-time, Transparency in production processes, reduced inventories, Improvements in the health and safety of workers, Maintenance processes standardization, Energy-efficient and environmentally sustainable production and systems, Effective use of human and material resources, and 100% traceability.

New opportunities will open up for SMEs with the Industrial Internet of Things (IIoT) and e-commerce platforms where they can offer tailor-made services and products using digital platforms. It will also enable them to internationalize and become micro-multinationals, generating new jobs and revenues, fuelling innovation and increasing efficiency. SMEs can benefit from lead firms in global value chains, offering new products and services to SMEs.